📄 PDF Documentation

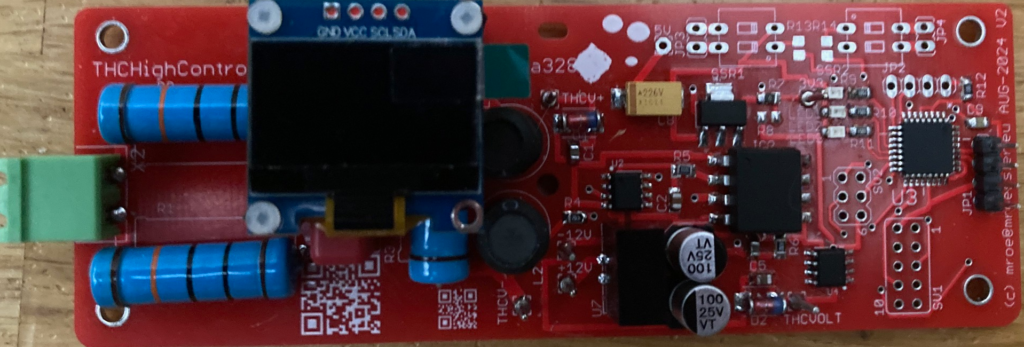

Function

-

- Voltage divider: 1:53 (optional)

- Connection of plasma cutter – Voltage divider must be connected before the pilot arc.

- Plasma cutter/CNC control separated by Optokoppler.

- 12V operating voltage from CNC control

- Max 5V input from voltage divider, if using voltage divider from PlasmaCutter

- Adjustable Plasma Voltage: 110V-150V via button

- LCD I2C display (5V)

- 3 LEDs – 2 Status indicators: THCUP, THCDOWN

- Menu: Calibration, PlasmaSoll, ResetToDefault, Active State LOW/HIGH,

Simple Hardware Test, Disable LCD Update during cut, About THC Controller

- 3 buttons: SELECT, UP, DOWN (for menu navigation)

- PCB 2xSSR OMRON G3VM-61 relays not assampled (no function in software yet)

- Programmable via ISP AVRDUDE (code in Arduino IDE, partially low-level)

⚠️ Safety Warning and Disclaimer

Warning: This tool is used for installation at the user’s own risk. High voltage (>50V) can be lethal. Ensure safe handling.

Disclaimer: Any liability for damages, particularly personal injury or property damage, arising from improper use of this tool is excluded to the extent legally permitted. The user assumes full responsibility for the safe and proper use of this tool during installation and operation.

🛠️ Connection to CNC Plasma

Connection Pins THC Controller

Connection setup for CNC Plasma with THC Controller.Continue reading