Generated Gcode with Eagle –> pcb-gcode.ulp

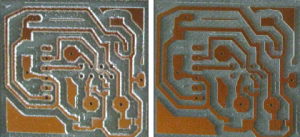

It’s very important to have a clamp with a run out (circulation) as small as possible. See picture bellow (left I used a bad clamp and on the right a good one). With same mill

PCB on the right has been milled with about double feed rate

Used tool 60° VHM Mill

Generation Options

Feed rate X,Y: 500mm/s

Spot drill holes: -0.55mm

Minimum: 0.0254mm

Maximum: 1.6mm

Step Size: 0.127mm

Maschine Z Down: -0.2mm

Tool Dia: 0.23094mm

–> dependend on ZDown and Mill° (60° and -0.2) –> Calculated –> (tan(30°)*2)*ZDown= 0.23094mm

| Angle ° | Z Down (-) | Tool Dia |

|---|---|---|

| 60° | 0.2mm | 0.23094mm |

| 60° | 0.15mm | 0.17324mm |

| 30° | 0.2mm | 0.10718mm |

| 30° | 0.15mm | 0.08038mm |

GCode Style

–> Mach3